How Does a Thermal Overload Protector Safeguard Motors and Electrical Equipment from Overheating?

In modern electrical systems, motors and other equipment are the backbone of countless industrial, commercial, and domestic applications. However, these devices are vulnerable to overheating due to overcurrent, prolonged operation, or abnormal conditions. Enter the Thermal Overload Protector (TOP)—a critical safety device designed to prevent motor damage, reduce downtime, and enhance operational safety. But what exactly is a thermal overload protector, how does it work, and why is it indispensable in today’s electrical systems?

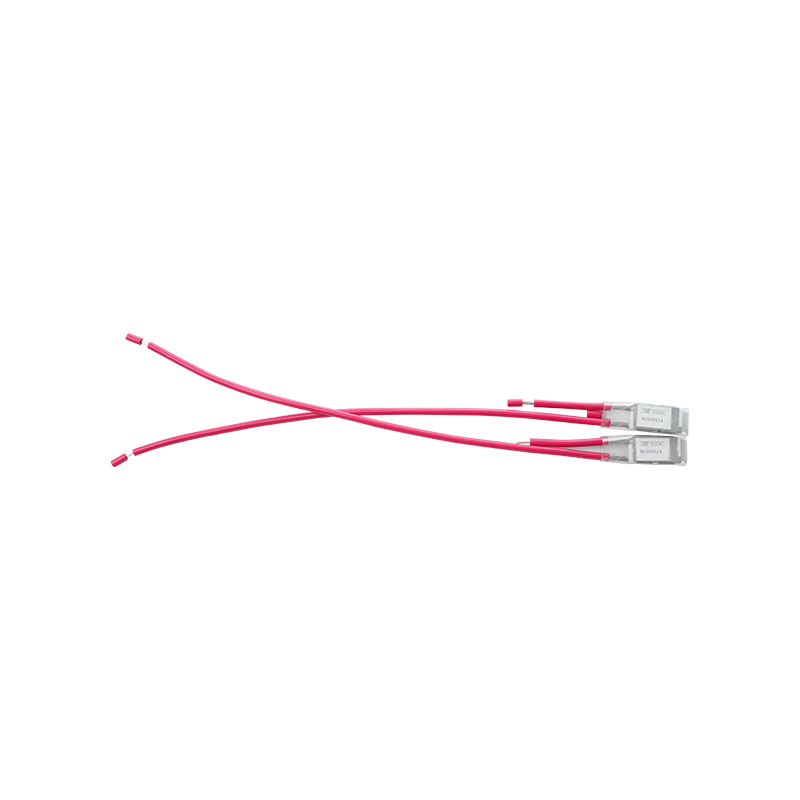

What Is a Thermal Overload Protector?

A thermal overload protector is an electrical safety device that automatically interrupts the power supply to a motor or equipment when it detects excessive temperature caused by overcurrent or mechanical overload. Essentially, it acts as a guardian against overheating, protecting both the device and the surrounding system from potential hazards.

Typically integrated into motors, compressors, pumps, and HVAC systems, thermal overload protectors are compact, reliable, and capable of responding rapidly to abnormal conditions.

Why Are Thermal Overload Protectors Important?

Overheating can lead to several serious issues:

Motor Damage – Excessive heat can degrade insulation, melt windings, and shorten the motor’s lifespan.

Operational Downtime – Equipment failure due to overheating can halt production or essential services.

Safety Hazards – Overheated motors may spark fires or cause electrical shocks.

Increased Maintenance Costs – Frequent failures demand costly repairs or replacements.

By detecting and interrupting overcurrent before it causes damage, thermal overload protectors ensure safety, reliability, and cost-efficiency.

How Does a Thermal Overload Protector Work?

The operation of a thermal overload protector is based on temperature-sensitive components that respond to abnormal heat:

Bimetallic Strip – Most thermal protectors use a bimetallic strip composed of two metals with different thermal expansion rates. When current exceeds the rated limit, the strip heats up, bends, and triggers a switch to cut off the circuit.

Reset Mechanism – Some protectors reset automatically after cooling down, while others require manual resetting.

Calibration – Each protector is calibrated to a specific current or temperature range suitable for the motor or equipment it protects.

This simple yet effective mechanism ensures reliable protection without the need for complex electronics.

What Types of Thermal Overload Protectors Exist?

Thermal overload protectors come in various types to suit different applications:

Manual Reset Thermal Protectors – Require user intervention to restore operation after tripping. Ideal for applications where inspection is needed before restarting.

Automatic Reset Thermal Protectors – Automatically resume operation once the temperature returns to safe levels. Suitable for systems where minimal downtime is crucial.

Bimetallic Thermal Protectors – Utilize a bimetallic strip for precise thermal response.

Thermistor-Based Protectors – Use temperature-sensitive resistors for more accurate and sensitive control in electronic applications.

Choosing the right type depends on the specific equipment, safety requirements, and operational needs.

How Are Thermal Overload Protectors Installed?

Installation typically involves:

Series Connection with Motor Windings – The protector is wired in series so that current passes through it.

Integration with Starter or Relay – Often installed alongside contactors or relays for easy tripping and control.

Proper Sizing – The protector must match the motor’s rated current and operating temperature to ensure accurate protection.

Correct installation is critical to ensure the protector functions effectively and does not cause nuisance trips or fail to prevent damage.

How Does a Thermal Overload Protector Protect Motors?

Motors are susceptible to thermal stress when:

Overloaded mechanically (too much torque).

Operated continuously at high currents.

Running in high ambient temperatures.

The thermal overload protector responds by interrupting the circuit before the motor reaches dangerous temperatures, preventing insulation breakdown, winding deformation, and catastrophic motor failure.

Where Are Thermal Overload Protectors Commonly Used?

These devices are ubiquitous across various industries and applications, including:

Industrial Motors – Pumps, conveyor belts, compressors, and production machinery.

HVAC Systems – Air conditioners, heat pumps, and ventilation fans.

Household Appliances – Washing machines, refrigerators, dryers, and ovens.

Automotive Applications – Electric motors in hybrid and electric vehicles.

Commercial Equipment – Elevators, escalators, and refrigeration units.

Their widespread adoption underscores their importance in maintaining safety and operational efficiency.

What Are the Benefits of Using a Thermal Overload Protector?

Equipment Longevity – Prevents motor overheating and premature failure.

Safety Assurance – Reduces the risk of fire, electrical shock, and damage to connected systems.

Reduced Downtime – Limits unexpected breakdowns and production interruptions.

Cost Efficiency – Minimizes repair costs and extends the service life of equipment.

Versatility – Suitable for a wide range of electrical and mechanical devices.

These advantages make thermal overload protectors an essential component in both residential and industrial systems.

Are Thermal Overload Protectors Reliable?

Yes, they are considered highly reliable due to:

Mechanical Simplicity – Few moving parts reduce failure probability.

Proven Technology – Decades of successful applications across industries.

Robust Construction – Resistant to vibration, moisture, and moderate environmental conditions.

Precise Calibration – Designed to activate within specified thermal and current limits.

With proper selection and installation, thermal overload protectors provide dependable protection for years.

How Do You Choose the Right Thermal Overload Protector?

When selecting a thermal protector, consider:

Rated Current and Voltage – Must match motor specifications.

Operating Environment – Temperature extremes, humidity, and vibration tolerance.

Reset Type – Manual or automatic based on application requirements.

Trip Accuracy – Ensures the device trips at the correct temperature to prevent damage.

Size and Mounting – Should fit the available space and integrate with existing electrical components.

Correct selection is crucial for optimal protection and equipment performance.

Maintenance and Testing of Thermal Overload Protectors

Although thermal overload protectors are low-maintenance, periodic inspection ensures continued reliability:

Visual Inspection – Check for physical damage, corrosion, or loose connections.

Functional Testing – Simulate overload conditions to ensure the protector trips correctly.

Calibration Check – Verify that the trip settings are still accurate, especially in industrial applications.

Replacement – Replace worn-out or malfunctioning protectors to maintain protection standards.

Regular maintenance reduces the risk of equipment failure and ensures long-term operational safety.

Final Thoughts: Why Is a Thermal Overload Protector Essential?

The thermal overload protector is a small but indispensable device that safeguards motors and electrical equipment from overheating. Its ability to prevent damage, ensure safety, reduce downtime, and extend equipment life makes it vital for industrial, commercial, and residential applications.

English

English