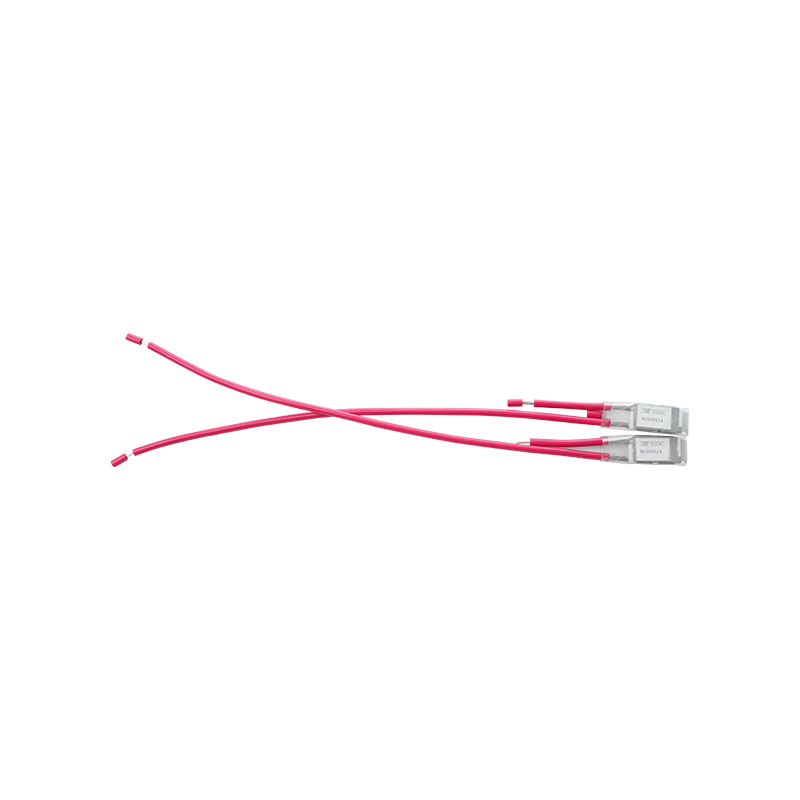

Thermal Overload Protector: The core component to protect the safe operation of motors

In modern industrial automation and household appliances, motors are widely used in fans, air conditioners, water pumps, compressors, washing machines and other equipment as key power sources. However, motors are easily damaged due to overload or overheating during long-term operation or under abnormal conditions, thus affecting the stability and safety of the entire system. Thermal Overload Protector is the core component to prevent this type of failure. It provides all-round overload protection for motors and equipment with a sensitive temperature control mechanism.

The thermal overload protector is a protective device that automatically cuts off the circuit according to temperature changes. Its working principle is based on the thermal expansion and contraction characteristics of the bimetallic strip. When the motor current increases abnormally and the temperature rises to the preset threshold, the bimetallic strip inside the protector will bend rapidly and the contacts will be disconnected, thereby cutting off the circuit and preventing the motor from burning due to excessive temperature rise. After the temperature drops, the protector returns to its original state, the circuit is reconnected, and the equipment continues to operate.

The advantages of thermal overload protectors are mainly reflected in the following aspects:

Real-time protection and fast response: The thermal overload protector has extremely high thermal sensitivity and can respond promptly at the initial stage of motor overload to prevent equipment damage caused by continuous operation.

Compact structure and easy installation: The small volume design is suitable for various types of electric equipment and can be directly integrated into the motor or power supply line for easy wiring and maintenance.

High reliability and long life: It adopts high-quality bimetallic materials, undergoes strict temperature control calibration and durability testing to ensure long-term stable operation.

Wide applicability: It can be applied to single-phase and three-phase motors, covering a variety of application scenarios such as household appliances, industrial equipment, and small motors.

Economical and practical, cost-controllable: As a passive protection element, the thermal overload protector does not require additional power supply or complex circuit control, and has a very high cost performance.

Under the background of the continuous advancement of intelligent manufacturing and energy-saving and environmental protection concepts, the role of thermal overload protectors in motor control systems is becoming more and more important. It not only reduces the risk of motor shutdown due to faults, but also extends the service life of the equipment, improves the safety and reliability of the entire machine, and is an indispensable safety line in modern electrical systems.

We provide thermal overload protector products of various specifications, support customized current range, action temperature and packaging method,

English

English