Why Are Thermal Overload Protectors Important for Electric Motors?

Electric motors are fundamental components in a wide range of applications, from industrial machinery and HVAC systems to household appliances and electric vehicles. Their efficiency, longevity, and performance are critical to ensuring smooth operations across these sectors. However, electric motors are vulnerable to overheating, which can occur due to excessive load, mechanical faults, voltage fluctuations, or inadequate cooling. Overheating not only reduces efficiency but can also lead to permanent damage or safety hazards such as fires.

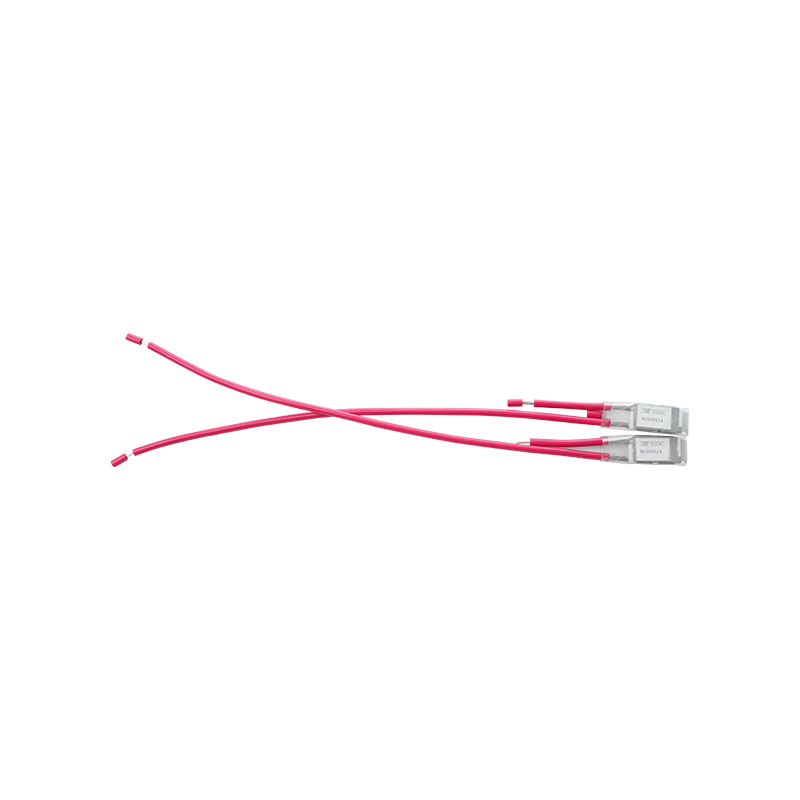

This is where thermal overload protectors (TOPs) play a vital role. A thermal overload protector is a safety device that automatically interrupts the electrical circuit when the motor temperature exceeds a safe threshold. By preventing overheating, these protectors safeguard the motor, prolong its lifespan, and ensure operational reliability. This article explores why thermal overload protectors are essential for electric motors, their working principles, benefits, and key considerations for selection and use.

1. Understanding Thermal Overload Protectors

A thermal overload protector is an electromechanical or electronic device designed to monitor the temperature of a motor or its winding. When excessive heat is detected, the device interrupts the current, preventing further temperature rise and potential damage.

Key Components of a Thermal Overload Protector:

Bimetallic Strip: A common mechanism where two metals with different expansion rates bend when heated, triggering a switch to cut off power.

Thermistors (PTC/NTC): Electronic sensors that detect temperature changes and provide a signal to trip the motor.

Reset Mechanism: Many TOPs feature either manual reset (requiring human intervention) or automatic reset (restoring power after cooling).

Thermal overload protectors are widely used in single-phase and three-phase motors, including induction motors, compressor motors, and fan motors, making them indispensable across industrial, commercial, and residential applications.

2. Preventing Motor Overheating

The primary function of a thermal overload protector is to prevent motor overheating, which is one of the leading causes of motor failure. Overheating can occur due to several reasons:

Excessive Load: Operating a motor above its rated capacity generates additional heat, stressing the windings and insulation.

Mechanical Issues: Bearing failure, shaft misalignment, or obstructions can increase friction, raising the motor’s temperature.

Electrical Faults: Voltage spikes, phase imbalances, or short circuits can cause overheating and damage the motor windings.

Poor Ventilation: Blocked cooling vents or inadequate airflow reduces the motor’s ability to dissipate heat.

By monitoring temperature and cutting off current during abnormal conditions, thermal overload protectors prevent irreversible damage, maintaining both motor performance and safety.

3. Protecting Motor Windings and Insulation

The winding insulation inside electric motors is highly sensitive to temperature. Excessive heat can degrade insulation, leading to short circuits or winding failure. Replacing damaged windings can be costly and time-consuming, especially for large industrial motors.

Thermal overload protectors ensure:

Insulation Longevity: Limiting temperature exposure preserves insulation materials and prevents deterioration.

Motor Reliability: Preventing overheating reduces unscheduled downtime and maintenance costs.

Consistent Performance: Motors protected by TOPs maintain their efficiency and torque output over time.

4. Enhancing Safety

Electric motors generate heat, and if overheating is unchecked, they can pose serious safety hazards:

Fire Risks: Excessive heat can ignite insulation, nearby materials, or even flammable liquids in industrial settings.

Electrical Hazards: Overheated motors can cause arcing, short circuits, or damage to connected circuits.

Operational Safety: Protecting the motor ensures that operators and maintenance personnel are not exposed to sudden failures or dangerous conditions.

By incorporating thermal overload protectors, facilities can significantly reduce the likelihood of accidents, protecting both personnel and property.

5. Reducing Maintenance Costs

Without thermal protection, motors are prone to frequent breakdowns due to overheating, resulting in higher repair and replacement costs. Thermal overload protectors help reduce maintenance expenses by:

Preventing Catastrophic Failures: Instead of allowing gradual insulation degradation, TOPs interrupt power before severe damage occurs.

Extending Motor Life: By maintaining safe operating temperatures, TOPs prolong the overall lifespan of the motor.

Minimizing Downtime: Avoiding motor burnout ensures continuous operations, which is especially critical in manufacturing and industrial processes.

6. Improving Operational Efficiency

Overheated motors often draw excessive current and operate less efficiently, increasing energy consumption and operational costs. Thermal overload protectors maintain optimal motor performance by:

Ensuring Stable Temperature: Motors run within safe thermal limits, preventing efficiency drops.

Reducing Energy Loss: By avoiding overcurrent conditions caused by overheating, energy consumption is optimized.

Supporting Preventive Maintenance: Early tripping alerts maintenance teams to potential issues, allowing for timely intervention.

7. Types of Thermal Overload Protectors

Thermal overload protectors come in various types, tailored to different applications:

1. Bimetallic Thermal Overload Protectors

Use a bimetallic strip that bends with heat, opening a switch to interrupt current.

Common in small household appliances and single-phase motors.

2. Electronic Thermal Overload Protectors

Use thermistors or temperature sensors to monitor heat electronically.

Provide precise temperature control and are suitable for modern industrial motors.

3. Manual Reset vs. Automatic Reset

Manual Reset: Requires human intervention to restore power, ensuring inspection before restart.

Automatic Reset: Restores power after the motor cools down, offering convenience but requiring careful monitoring to avoid repeated tripping in case of persistent issues.

8. Selection Considerations for Thermal Overload Protectors

Choosing the right TOP for a motor involves considering:

Motor Type and Size: Ensure the TOP is compatible with the motor’s voltage, current, and phase.

Environment: High-temperature or dusty environments may require specialized protectors with higher tolerance.

Reset Mechanism: Decide between manual and automatic reset based on safety and convenience requirements.

Accuracy and Sensitivity: Select a TOP with precise temperature sensing to avoid nuisance tripping or delayed protection.

9. Real-World Applications

Thermal overload protectors are used in a wide range of applications:

Industrial Machinery: Lathes, pumps, conveyors, and compressors.

HVAC Systems: Motors in air conditioners, heaters, and ventilation fans.

Household Appliances: Refrigerators, washing machines, and dryers.

Renewable Energy: Motors in solar and wind energy systems.

In each case, the TOP ensures that the motor operates safely and efficiently, regardless of load conditions or environmental factors.

Conclusion

Thermal overload protectors are critical components for electric motor protection. They safeguard motors against overheating, preserve winding insulation, enhance operational safety, reduce maintenance costs, and improve energy efficiency. By interrupting power during excessive temperature conditions, TOPs prevent catastrophic failures and extend motor lifespan.

Whether in industrial machinery, HVAC systems, or household appliances, incorporating a thermal overload protector ensures reliable and safe motor operation. As modern electrical systems become increasingly complex, TOPs remain indispensable devices that combine functionality, safety, and efficiency, making them a crucial investment for both residential and industrial applications.

English

English