Why is a thermal overload protector important in preventing motor overheating?

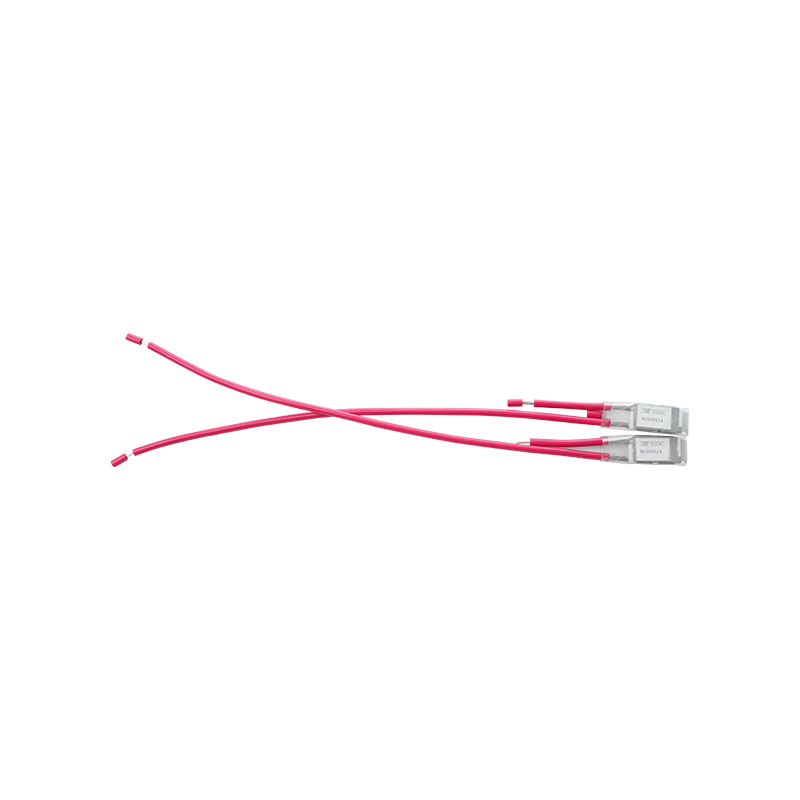

Introduction to Thermal Overload Protectors

Thermal overload protectors are critical components in electrical motors and machinery. They are designed to prevent overheating by automatically disconnecting the power supply when the motor temperature exceeds safe limits. Overheating can cause permanent damage, reduce efficiency, and even pose fire hazards. Understanding the role and function of thermal overload protectors is essential for industrial operators, maintenance engineers, and anyone using electrical motors.

How Thermal Overload Protectors Work

Thermal overload protectors operate based on the principle of temperature-sensitive elements that detect excessive heat. Typically, they contain bimetallic strips or thermistors that bend or change resistance when a critical temperature is reached. This action triggers a switch that interrupts the electrical circuit, stopping the motor to prevent further heat accumulation.

Bimetallic Strip Mechanism

A bimetallic strip consists of two metals with different thermal expansion rates bonded together. When the motor overheats, the strip bends due to unequal expansion, opening the circuit. This mechanism is highly reliable and widely used in single-phase and three-phase motors.

Thermistor-Based Protection

Thermistors are temperature-sensitive resistors. As the motor temperature rises, the resistance of the thermistor changes, signaling the control unit to cut off power. This system is often used in modern smart motors for precise temperature monitoring.

Importance in Preventing Motor Overheating

Motor overheating is one of the leading causes of electrical equipment failure. Thermal overload protectors provide a first line of defense by reducing risks associated with excessive temperatures. Overheating can result from:

- Electrical overload due to excessive current

- Mechanical load beyond rated capacity

- Poor ventilation or blocked airflow

- Ambient temperature fluctuations

By detecting temperature rises early, thermal overload protectors prevent insulation breakdown, reduce wear on mechanical components, and minimize downtime due to motor failures.

Types of Thermal Overload Protectors

Different types of thermal overload protectors are used depending on the motor type and application. Key types include:

Manual Reset Overload Protectors

These require the operator to manually reset the device after it trips. They are suitable for applications where occasional overheating is expected and human intervention is acceptable.

Automatic Reset Overload Protectors

Automatic reset types restore the power supply after the motor cools down. They are commonly used in motors where continuous operation is critical, but care must be taken to prevent repeated overheating cycles that could damage the motor.

Benefits of Using Thermal Overload Protectors

Installing a thermal overload protector offers numerous benefits for industrial and residential applications:

- Motor Longevity: Prevents insulation and winding damage.

- Safety: Reduces risk of fires and electrical hazards.

- Cost Savings: Avoids expensive repairs and replacement of motor components.

- Efficiency: Minimizes downtime and maintains production continuity.

- Environmentally Friendly: Reduces energy waste due to overheating inefficiencies.

Applications of Thermal Overload Protectors

Thermal overload protectors are used across various industries and applications where motors are integral. Key applications include:

- Industrial machinery such as conveyors, pumps, and compressors

- HVAC systems including fans and air conditioning units

- Home appliances like washing machines, dryers, and refrigerators

- Automotive motors in electric vehicles and hybrid systems

- Renewable energy equipment including wind turbines and solar pumps

Installation and Maintenance Considerations

Proper installation and maintenance of thermal overload protectors are critical for effective performance. Key points include:

Correct Sizing

Selecting the correct protector based on motor current rating and operating conditions ensures accurate tripping and prevents nuisance shutdowns.

Regular Inspection

Inspecting the device for wear, corrosion, or mechanical damage ensures reliability. Over time, thermal protectors may lose sensitivity and need replacement.

Integration with Control Systems

Modern thermal overload protectors can be integrated with digital monitoring systems to provide real-time alerts and data for predictive maintenance.

Conclusion

Thermal overload protectors play an essential role in safeguarding motors against overheating. By automatically disconnecting power when critical temperatures are reached, they prevent equipment damage, reduce maintenance costs, and enhance safety. Whether in industrial machinery, home appliances, or renewable energy systems, understanding and utilizing thermal overload protection ensures longevity, reliability, and efficiency of motors.

English

English