Bimetal Thermostat Circuit Breaker Manufacturers

The company manufactures bimetal circuit breakers, available in both normally closed and normally open configurations, utilizing the principle of bimetallic strip expansion to interrupt the electrical circuit when excessive current flows, providing overcurrent protection for a wide range of applications, including motor protection, appliance safety, and industrial control systems.

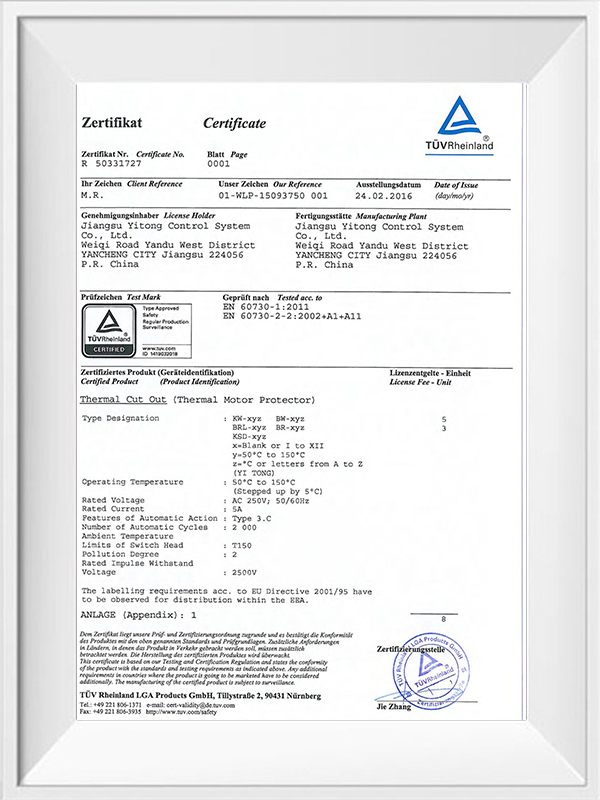

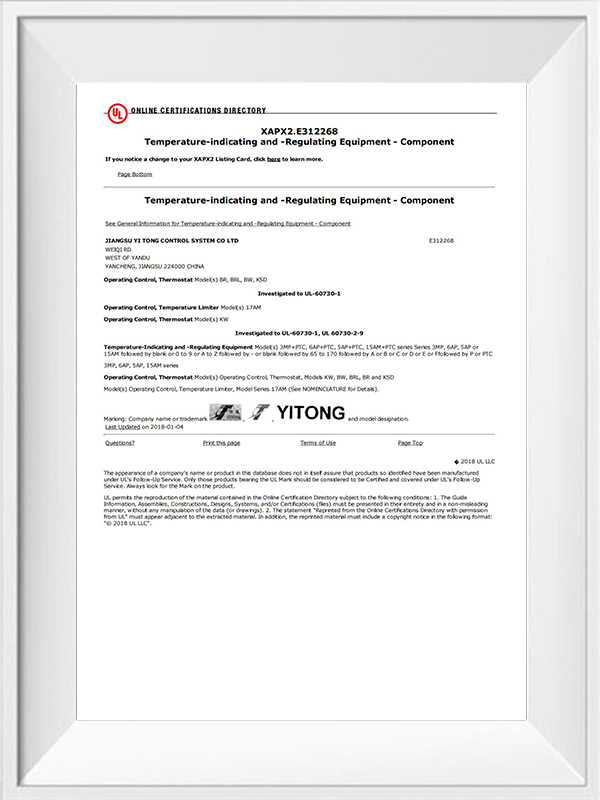

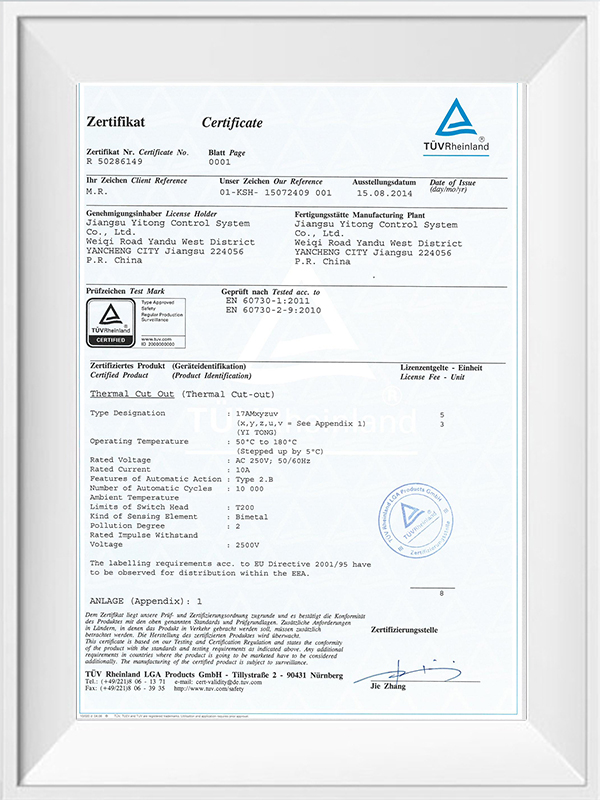

As China Bimetal Thermostat Circuit Breaker Manufacturers and Bimetal Thermostat Circuit Breaker Factory .The company has a strong ability to develop, produce, and test. We have invested a lot in researching and developing new products by introducing abroad new and advanced technology, such as the automatic production line from Japan. The management system is strictly carried out according to the ISO9001. We Wholesale Bimetal Thermostat Circuit Breaker.Our vision is to pursue excellence, develop the Yitong brand, obey integrity, and meet the requests of the customers. Intensify the quality monitoring and management, and proceed with normalized and standardization management. Construct the company culture and strengthen the core competitiveness.

-

A 17AM thermal protector is a compact temperature-sensitive safety device designed to protect electric motors, compresso...

-

Electric motors are vital components in industrial machinery, HVAC systems, appliances, and many other applications. How...

-

Temperature Switch Protectors are thermal safety devices designed to monitor temperature changes and interrupt or contro...

-

Bimetal thermostat temperature switches are precision devices designed to monitor and control temperature in various sys...

Bimetal Circuit Breaker Industry knowledge

Unlocking the Secrets of Bimetal Thermostat Circuit Breakers: A Deep Dive into Material Science

When it comes to safeguarding electrical systems, few components are as reliable and versatile as bimetal thermostat circuit breakers . These ingenious devices, which leverage the thermal expansion properties of bimetallic strips, have become indispensable in applications ranging from motor protection to appliance safety. At Shanghai Jushi Science and Technology Co., Ltd., alongside our sister company Jiangsu Yitong Control System Co., Ltd., we’ve spent years perfecting the art and science of thermal protection. With over 60 million units of various protectors produced annually—including models like 17AMG and KW—we understand the intricacies of these devices better than most. Let’s explore one of the most fascinating aspects of their design: the material science behind bimetallic strips.

At the heart of every bimetal thermostat circuit breaker lies a carefully engineered bimetallic strip. This strip is composed of two distinct metals bonded together, each with different coefficients of thermal expansion. When exposed to excessive current, the resistive heating causes the strip to bend, triggering the mechanism that interrupts the circuit. The choice of alloys used in these strips is critical to the performance of the device. For instance, materials like copper-nickel or steel-brass combinations are often selected for their ability to balance sensitivity, durability, and cost-effectiveness. At Jushi, we’ve invested heavily in researching advanced alloy compositions to optimize the responsiveness of our bimetallic strips. By introducing cutting-edge technologies, such as automated production lines from Japan, we ensure that every strip meets the highest standards of precision and reliability.

But what happens when these materials are subjected to prolonged use? Over time, the repeated heating and cooling cycles can lead to material fatigue, potentially affecting the calibration of the circuit breaker. This is where our expertise in long-term material degradation comes into play. Our team has conducted extensive lifecycle testing to understand how factors like ambient temperature, humidity, and mechanical stress impact the performance of bimetallic strips. For example, in environments with extreme temperatures—such as industrial settings or outdoor applications—we’ve developed specialized coatings and heat-resistant alloys to enhance durability. This ensures that our bimetal circuit breakers remain accurate and reliable, even under challenging conditions.

Another key consideration is how these materials interact with the broader system. In high-current applications, such as motor protection or transformer safety, the thermal dynamics of the bimetallic strip must be finely tuned to prevent overheating while avoiding unnecessary tripping. At Yitong, we’ve developed proprietary techniques to model and simulate the thermal behavior of our strips under varying loads. This allows us to calibrate our bimetal thermostat circuit breakers with remarkable precision, ensuring they meet the specific needs of our customers. Whether it’s protecting an electric heater or safeguarding a complex industrial control system, our products are designed to deliver consistent performance.

Our commitment to quality extends beyond the materials themselves. As a leading China 17AM thermal protectors manufacturer , we adhere to strict ISO9001 standards, ensuring that every step of the production process—from raw material selection to final assembly—is meticulously monitored. With a factory spanning over 21,062 square meters and more than 100 dedicated staff, we have the capacity and expertise to meet the demands of global markets. Our vision is simple yet powerful: to develop the Yitong brand by prioritizing excellence, integrity, and customer satisfaction. This philosophy drives everything we do, from developing new products to refining existing ones.

English

English