Motor Thermal Protector Manufacturers

These types of motor thermal protectors (17AM, automatic reset self-holding fan thermal overload protector, Bimetal 7AM) are safety devices used to protect the motor from overheating damage. They detect the motor temperature and automatically cut off the power supply once the temperature exceeds the set value to prevent the motor from burning out. Among them, the 17AM series is famous for its compact size and fast response; the automatic reset and self-holding fan thermal overload protector has automatic reset and self-holding functions; the Bimetal 7AM uses a bimetallic sheet as the temperature sensing element, with a simple and reliable structure.

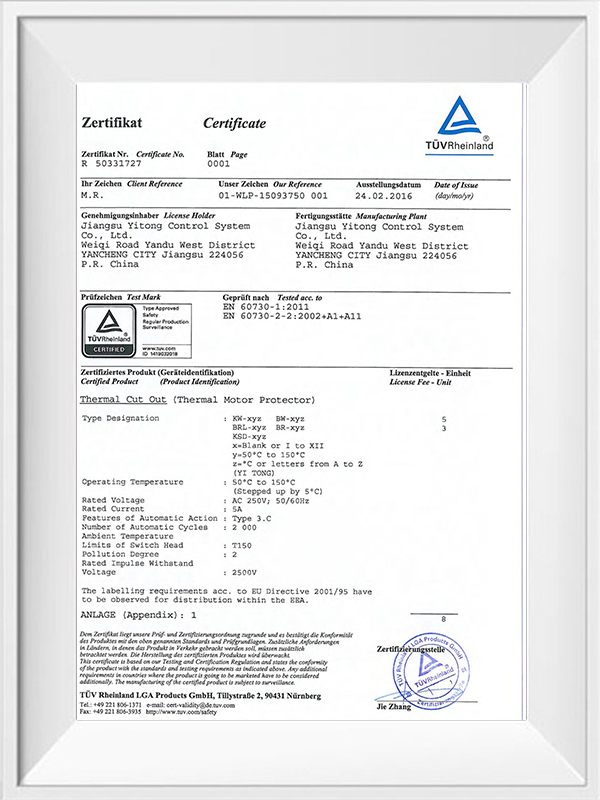

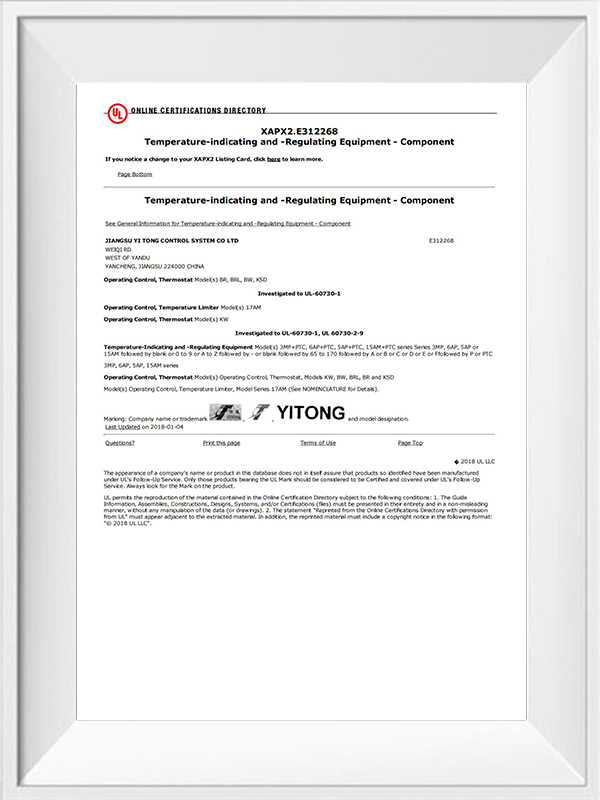

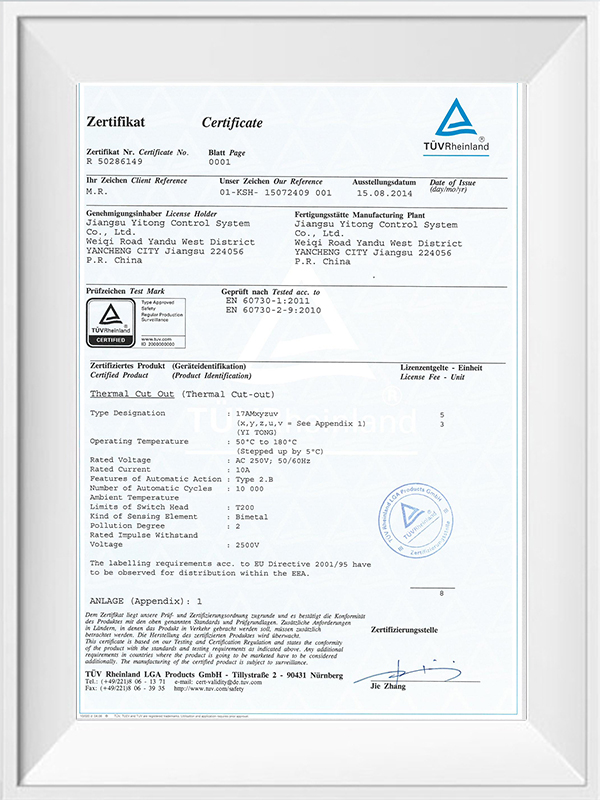

As China Motor Thermal Protector Manufacturers and Motor Thermal Protector OEM/ODM Factory .The company has a strong ability to develop, produce, and test. We have invested a lot in researching and developing new products by introducing abroad new and advanced technology, such as the automatic production line from Japan. The management system is strictly carried out according to the ISO9001. We Wholesale Motor Thermal Protector.Our vision is to pursue excellence, develop the Yitong brand, obey integrity, and meet the requests of the customers. Intensify the quality monitoring and management, and proceed with normalized and standardization management. Construct the company culture and strengthen the core competitiveness.

-

A 17AM thermal protector is a compact temperature-sensitive safety device designed to protect electric motors, compresso...

-

Electric motors are vital components in industrial machinery, HVAC systems, appliances, and many other applications. How...

-

Temperature Switch Protectors are thermal safety devices designed to monitor temperature changes and interrupt or contro...

-

Bimetal thermostat temperature switches are precision devices designed to monitor and control temperature in various sys...

Motor Thermal Protector Industry knowledge

How Does Shanghai Jushi Science and Technology Co., Ltd.'s Motor Thermal Protector Help Prevent Motor Damage?

Motor overheating is a significant concern in the world of electrical systems, and if left unchecked, it can lead to irreversible damage, reducing efficiency, and shortening the lifespan of equipment. Thankfully, advanced thermal protection systems, such as those produced by Shanghai Jushi Science and Technology Co., Ltd. and its sister company, Jiangsu Yitong Control System Co., Ltd., have revolutionized the way we protect motors from overheating. These protectors serve as the first line of defense, safeguarding both the motor and the broader electrical system.

Shanghai Jushi Science and Technology Co., Ltd. specializes in the manufacturing of high-quality motor thermal protectors, offering a robust range of products that include renowned models like the 17AMG, KW series, and others designed for various applications. These thermal protectors are engineered to monitor the temperature of the motor and automatically disconnect power when it reaches dangerous levels, thus averting damage.

The company’s extensive product line is built for versatility. The protectors find application across a spectrum of industries—ranging from motors and transformers to electrical tools and electric heaters. Whether it’s the fan in an industrial motor or a heating element in a household appliance, these protectors ensure the longevity and efficiency of the system by preventing overheating that could lead to catastrophic failure.

Precision and Reliability: The Core of Motor Protection

At the heart of these protectors lies cutting-edge technology. For instance, models like the 17AM series are known for their compact size and quick response. This ensures that the motor is promptly disconnected from power as soon as the temperature exceeds safe limits. A fast response is essential in preventing damage to sensitive motor components and preserving the integrity of the system.

One of the flagship offerings, the Bimetal 7AM, utilizes a bimetallic strip that flexes when exposed to excessive heat. This simple yet effective mechanism triggers a shutdown, halting the motor's operation before it suffers any harm. The structure is both straightforward and highly reliable, ensuring years of flawless operation with minimal maintenance.

In addition, the automatic reset and self-holding fan thermal overload protector plays a crucial role in ensuring that the motor remains protected and can resume normal operation once it cools down. The reset function, in particular, is a game-changer, reducing downtime and eliminating the need for manual intervention. Once the motor’s temperature drops to a safe level, the protector automatically restores the power supply, allowing the motor to function efficiently without constant monitoring.

A Commitment to Innovation and Quality

Jiangsu Yitong Control System Co., Ltd. operates a world-class facility that spans more than 21,000 square meters, housing over 100 skilled professionals. The company prides itself on its state-of-the-art production capabilities, with a capacity to produce up to 60 million units annually. The company’s focus on research and development allows for continuous innovation, keeping them ahead of market demands and setting industry standards.

By investing in cutting-edge technologies—such as the automatic production line sourced from Japan—the company has dramatically enhanced its ability to develop and manufacture thermal protectors that meet the highest standards of performance and reliability. Additionally, their adherence to the ISO 9001 management system guarantees that every product undergoes rigorous testing and quality assurance procedures, ensuring unparalleled consistency and reliability across the entire product range.

Meeting Diverse Industry Needs with Expertise

Shanghai Jushi and Jiangsu Yitong’s commitment to quality is evident in their diverse portfolio. Their motor thermal protectors are designed not just for motors, but for a variety of electrical systems, including transformers, rectifiers, and warmers. The company's ability to provide customized solutions tailored to each client’s specific needs is a testament to their deep understanding of the industries they serve.

Whether for residential or industrial applications, these protectors offer a fail-safe mechanism to protect critical equipment, keeping downtime to a minimum and maintaining operational efficiency. This level of protection is invaluable, particularly in mission-critical applications where motor failure can lead to significant financial losses or safety hazards.

English

English