17AM Thermal Protectors Manufacturers

We specializes in manufacturing a range of 17AM series thermal protectors, including sealed, thinner, and combined temperature/current control types, often incorporating Klixon technology, to offer reliable and versatile protection for various electrical and electronic devices.

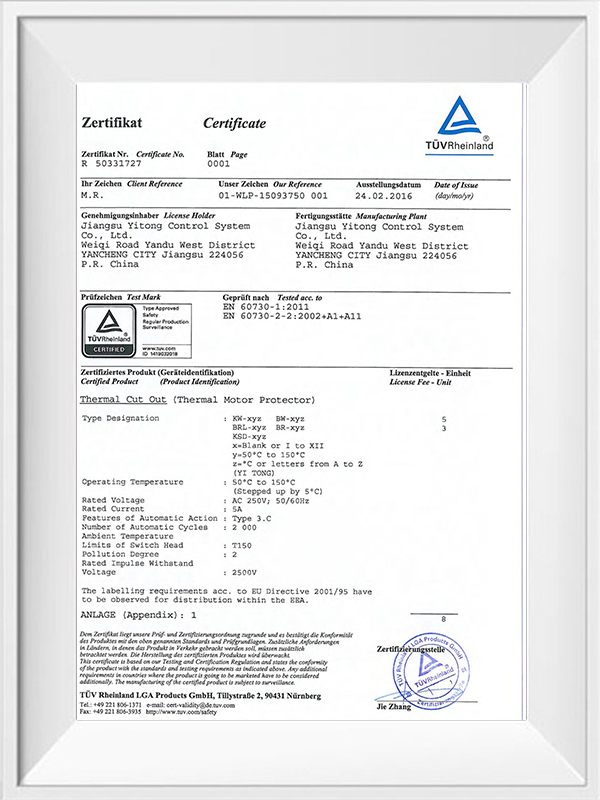

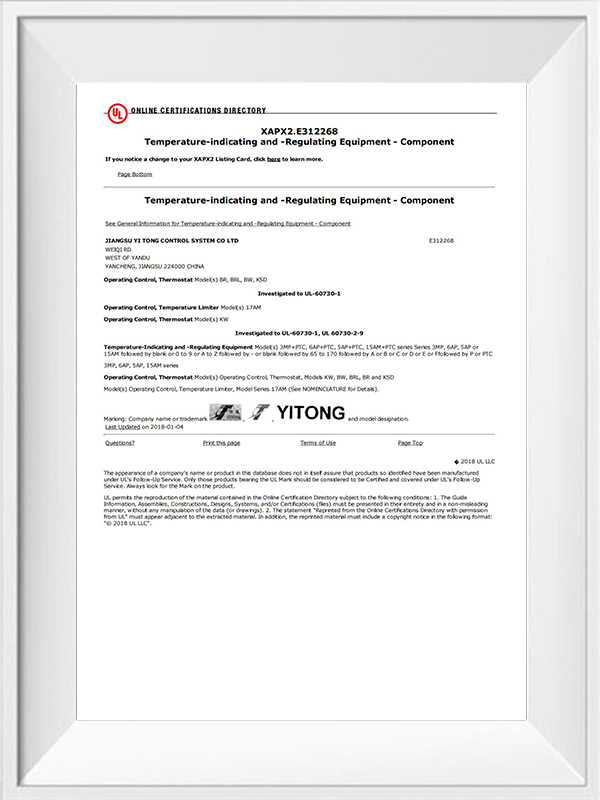

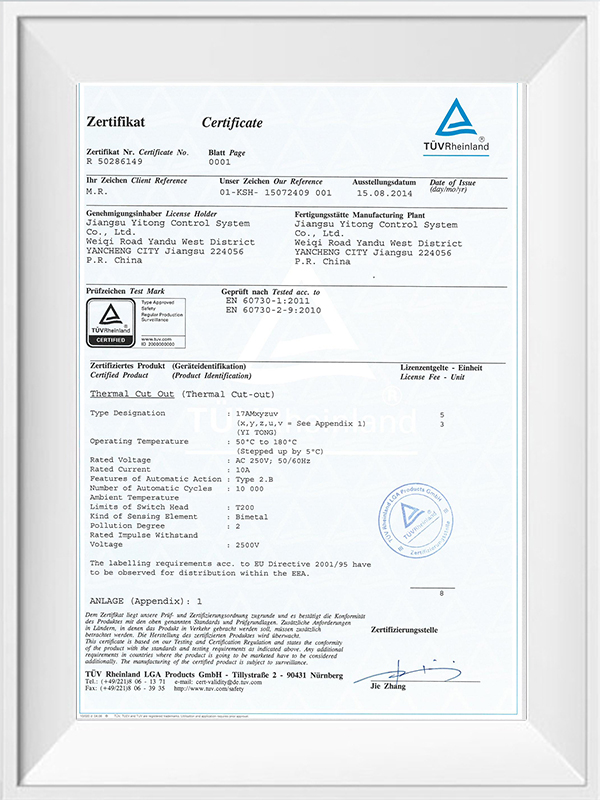

As China 17AM Thermal Protectors Manufacturers and 17AM Original Factory .The company has a strong ability to develop, produce, and test. We have invested a lot in researching and developing new products by introducing abroad new and advanced technology, such as the automatic production line from Japan. The management system is strictly carried out according to the ISO9001. We Wholesale 17AM Thermal Protectors.Our vision is to pursue excellence, develop the Yitong brand, obey integrity, and meet the requests of the customers. Intensify the quality monitoring and management, and proceed with normalized and standardization management. Construct the company culture and strengthen the core competitiveness.

-

A 17AM thermal protector is a compact temperature-sensitive safety device designed to protect electric motors, compresso...

-

Electric motors are vital components in industrial machinery, HVAC systems, appliances, and many other applications. How...

-

Temperature Switch Protectors are thermal safety devices designed to monitor temperature changes and interrupt or contro...

-

Bimetal thermostat temperature switches are precision devices designed to monitor and control temperature in various sys...

17AM Thermal Protector Industry knowledge

Mastering Heat Dissipation in Miniaturized Devices: The Role of 17AM Thermal Protectors

As devices shrink in size, the demand for reliable thermal management solutions like the 17AM thermal protector grows exponentially. At Shanghai Jushi Science and Technology Co., Ltd., alongside our sister company Jiangsu Yitong Control System Co., Ltd., we specialize in producing high-quality thermal protectors that cater to this exact need. With decades of experience and a robust production capacity of over 60 million units annually, we pride ourselves as a leading 17AM original factory , delivering cutting-edge solutions to industries worldwide.

When it comes to compact electronics—whether it’s a sleek smartphone, a portable power tool, or an advanced IoT device—the challenge isn’t just about fitting more components into a smaller space. It’s also about ensuring these components operate safely and efficiently without overheating. This is where thinner designs of the 17AM series thermal protectors come into play. Our team has meticulously engineered these protectors to not only fit seamlessly into tight spaces but also deliver exceptional performance. By leveraging advanced materials and precision manufacturing techniques, we’ve managed to reduce the form factor while maintaining the same level of reliability that our customers have come to expect.

One might wonder how material selection impacts the effectiveness of such protectors. In reality, the choice of materials plays a pivotal role in determining both thermal conductivity and response time. For instance, our sealed 17AM thermal protectors utilize specialized coatings that resist environmental factors like moisture and dust, ensuring consistent performance even in harsh conditions. These coatings don’t just enhance durability; they also allow for faster heat transfer, which is crucial when milliseconds matter. Moreover, as part of our commitment to innovation, we’ve invested heavily in state-of-the-art technology, including automated production lines imported from Japan. This ensures every unit meets stringent quality standards, adhering to ISO9001 guidelines and reflecting our dedication to excellence.

But what truly sets us apart as a 17AM original factory is our ability to adapt to industry-specific needs. Whether it’s motors, warmers, lights, transformers, or electrical tools, our protectors are designed with versatility in mind. Take, for example, the integration of our protectors into multi-layer printed circuit boards (PCBs). As electronic devices become increasingly complex, embedding thermal protection directly into PCBs has emerged as a game-changing solution. Our thinner 17AM protectors can be seamlessly incorporated into both rigid and flexible PCB designs, offering unparalleled thermal management without compromising on space. This capability has made us a trusted partner for manufacturers across diverse sectors, from consumer electronics to industrial automation.

Of course, none of this would be possible without our relentless focus on research and development. Operating out of a sprawling facility spanning over 21,062 square meters, our team of over a hundred skilled professionals works tirelessly to push the boundaries of what’s possible. From developing new bimetallic strip technologies to exploring eco-friendly materials, we’re constantly innovating to stay ahead of the curve. And because we understand the importance of customization, we offer tailored solutions to meet specific customer requirements, whether it’s adjusting voltage ratings or optimizing current thresholds.

English

English